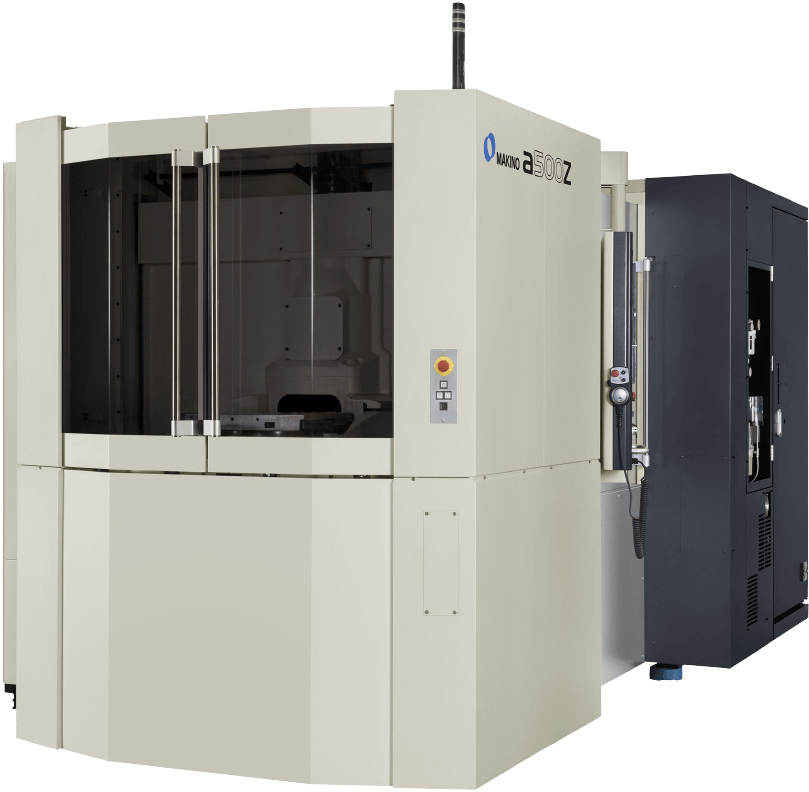

Pallet:

a500iR

The a500iR five axis horizontal machining center is built specifically for high-efficiency machining of small to medium size, complex production components such as monolithic aerospace parts. The a500iR’s unique pallet changer configuration combines the chip-shedding capability of an upright workpiece...