Additive Manufacturing (AM) has reached a point where the conversation is no longer limited to “What can we print?” but rather “How do we unlock greater value from what we print?” Among the most compelling answers is multi-material capability—the ability to combine distinct metals or material properties within a single build to enable new levels of functionality, integration, and performance.

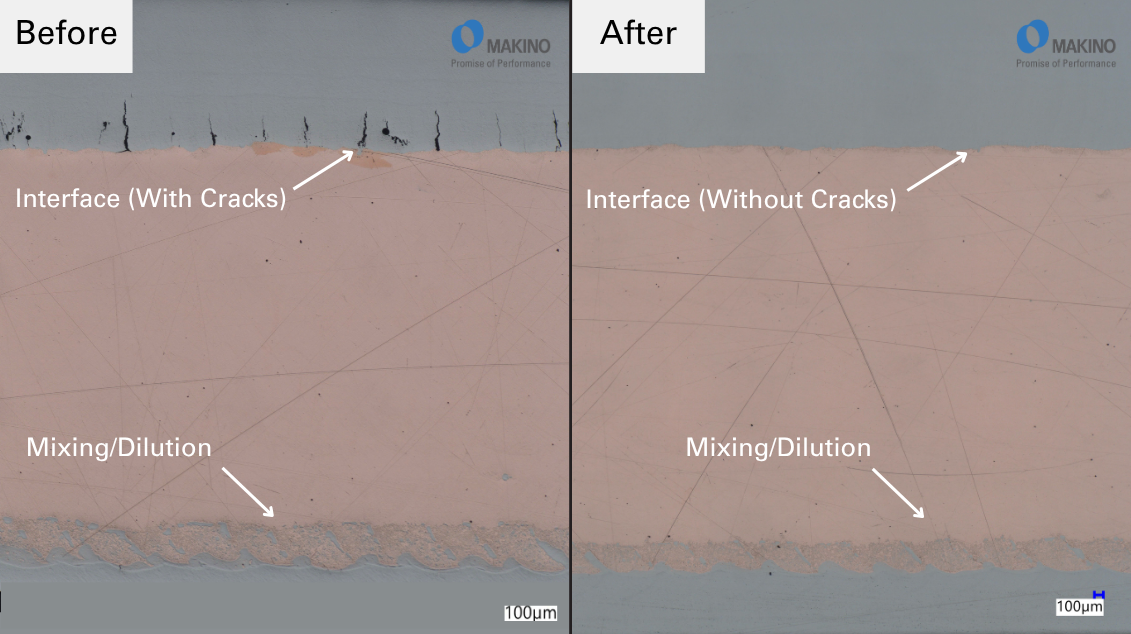

The benefits are clear: parts with localized wear resistance, embedded thermal management, or tailored mechanical properties—all without assembly or secondary operations. And yet, despite growing machine sophistication and a robust interest across industries, multi-material AM remains largely confined to research labs and technical demonstrators.

So, what’s the bottleneck?

At Makino AM,we have the capabilitlity to solve precisely this challenge. With deep expertise in material selection, hybrid processing, and design for multi-material AM, we help our customers transition from prototypes to product-ready solutions. Whether you're exploring performance-driven materials integration or need consultation on process optimzation and quality control, our team is ready to collaborate.

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

We believe the key isn’t just technical feasibility—it’s manufacturing confidence.

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)