.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

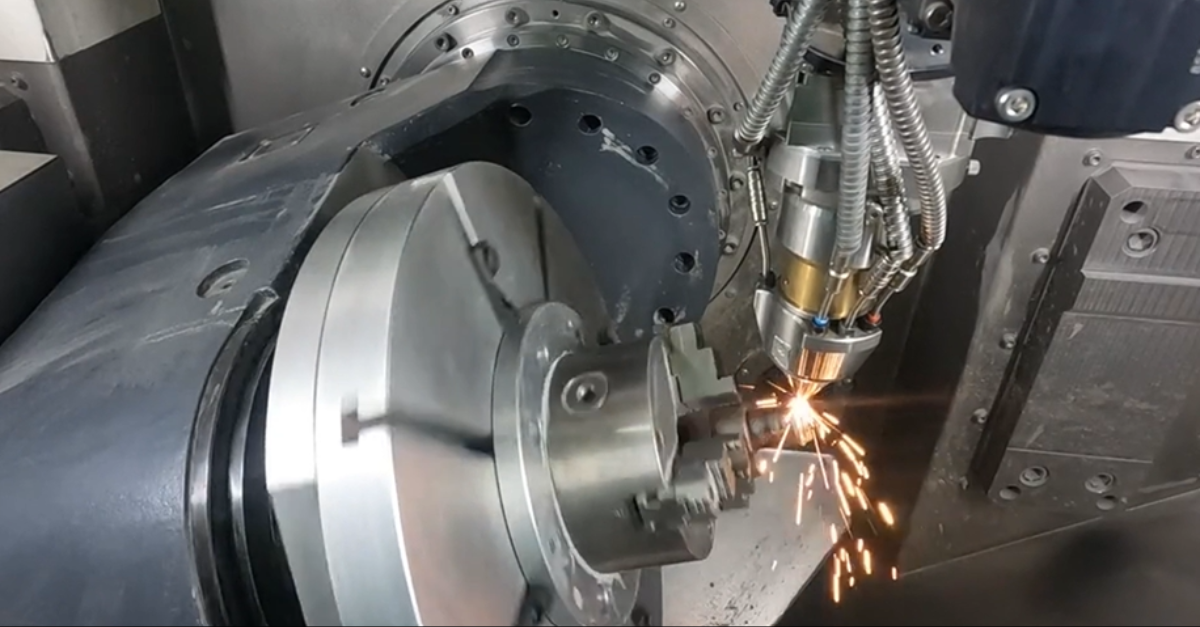

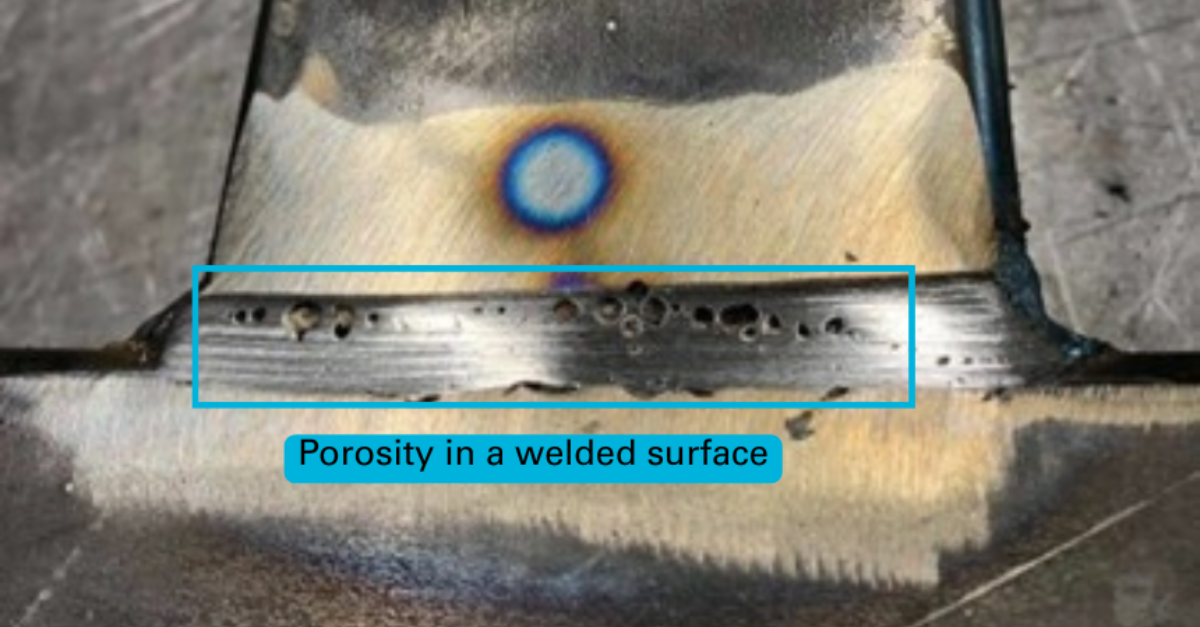

The existing repair method involves manual welding, followed by milling and electric discharge machining (EDM). However, this process often results in porosity, reduced hardness, and accelerated corrosion, leading to the need for frequent repairs. Welding serves as a temporary solution, introducing inconsistencies and increasing labor costs, while also causing significant machine downtime. These challenges underscore the need for a more efficient, long-term solution to optimize insert durability, reduce maintenance costs, and improve overall operational efficiency.

.png.aspx?width=1200&height=627&ext=.png&maxsidesize=960&resizemode=force)

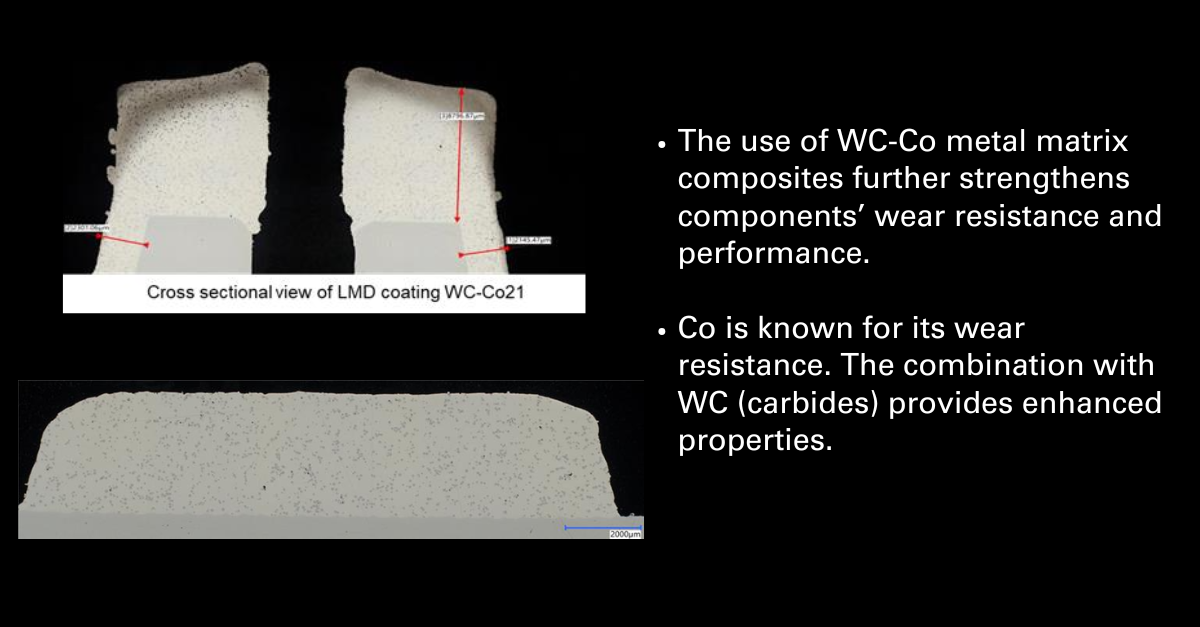

For the repair and enhancement of tools, we use Laser Metal Deposition (LMD) additive manufacturing to deposit a special material matrix, such as WC-Co21 (Cobalt21 alloy with 20% Tungsten Carbide). This process offers several key benefits: it improves surface quality by ensuring consistent, dense metal deposition that reduces porosity, achieving surface hardness comparable to or higher than tool steel.

LMD also enhances durability by increasing resistance to corrosion and prolonging the life of sub inserts. The automated nature of the process ensures precision and consistency, minimizing inconsistencies typically found in manual welding. Additionally, LMD reduces maintenance needs by decreasing the frequency of repairs or replacements, which in turn lowers machine downtime and associated costs. Ultimately, it acts as a long-term solution to enhance tool performance, improving both production efficiency and cost-effectiveness.

.png.aspx?width=1200&height=627&ext=.png&maxsidesize=960&resizemode=force)

After the LMD process, post-processing enhances the precision and surface quality of the part. Techniques such as EDM (Electrical Discharge Machining) are used selectively to achieve fine details and tight tolerances, particularly in areas with complex geometries. This hybrid approach results in tools with exceptional durability, improved performance, and extended service life.

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

The solution has demonstrated exceptional durability in real production conditions, with the repaired insert continuing to perform reliably over an extended period. Customer feedback highlights the effectiveness of the repair, noting that the insert still appears like new despite extensive use. Key benefits include a significantly increased lifespan of the inserts, reduced downtime, and lower replacement costs. This enhanced tool performance has translated into improved production efficiency and meaningful cost savings for the customer. The outcome underscores the value of by Laser Metal Deposition (LMD),in delivering long-term, cost-effective solutions.

.png)