At Makino Additive Manufacturing, we believe that real innovations don’t stop once a machine is built — it continues through every iteration, adjustments, and insights gained from day-to-day operations.

One recent focus area for our team has been about the optimization of the Laser Optics System in our AML900 LMD machine. While the Optics might not be the most visible part of the system, they play a critical role in how effectively the laser delivers energy to the material. And as we’ve seen, even subtle improvements in this area can translate to significant gains in overall print performance.

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

In Laser-Based Additive Manufacturing — especially with processes like Laser Metal Deposition (LMD) and High Speed LMD ((HS-LMD) — Beam Quality and Consistency are directly tied to a part’s quality. Misalignment, poor focus, or energy dispersion can lead to irregular melt pools, excessive heat-affected zones, and inconsistent layer bonding.

Here's how we optimize the technology over at Makino AM:

• Selecting the right specifications to ensure print optimization delivery for the required applications.

• Refining the laser spot size and focal length for sharper, more stable melt pools

• Path planning strategies to reduce variability

The goal was simple: To increase process stability without sacrificing speed.

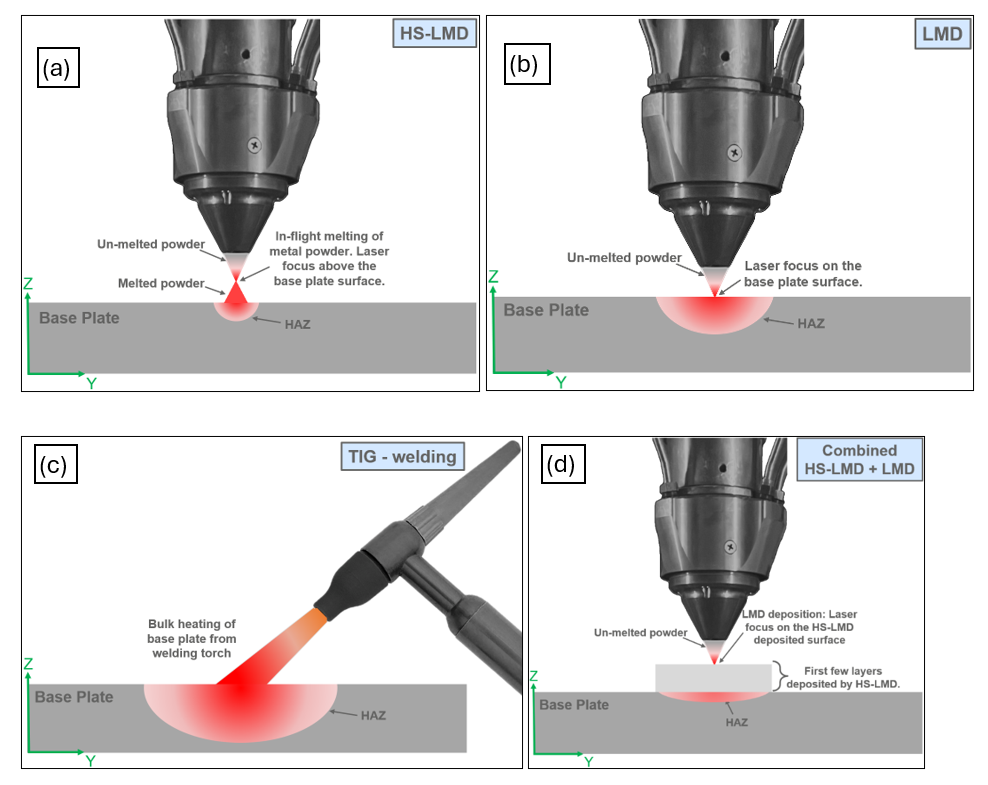

In HS-LMD coating and repair, maintaining base material integrity is critical, as excessive tensile residual stresses can reduce fatigue performance, cause distortion or cracking, and weaken the structure. Compared to traditional welding and earlier LMD, HS-LMD offers a superior solution for hard-facing and repair applications.

Key Highlights:

• Up to 80% reduction in residual stresses than conventional TIG welding

• Up to 75% reduction in residual stresses than LMD

• Predominantly compressive residual stresses induced on the surface by HS-LMD, as compared to tension dominant LMD

•Elimination of stress concentration at localized areas

Fig. 1 shows a Co6 coating fabricated by welding and Makino’s HS-LMD process. A significantly large HAZ denoted by the change in coloration caused by oxidation of the steel base plate during welding can be observed in Fig.1(a), whereas the HAZ from HS-LMD is barely visible as shown in Fig.1(b).

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)

The superior results from Makino’s HS-LMD over conventional methods of coating and repair is due to the unique characteristics of the in-flight melting in HS-LMD as illustrated in Fig. 2(a). As opposed to direct heating of the base plate in LMD and welding shown in Fig. 2(b) and 9(c), the in-flight melting in HS-LMD induces significantly less thermal gradient and therefore, stress in the base plate. As illustrated in Fig. 2(d), adopting a combined strategy of HS-LMD followed by LMD, the deeper and larger HAZ induced by LMD is buffered by the initial layers of HS-LMD depositions, therefore minimising the thermal effects on the base material.

.png)

Final Thoughts

To achieve high quality coating with desirable properties, the optics system of the AML900 has specific features that include capability for process monitoring and control, where critical deposition parameters such as the laser power, powder mass flow rate and shielding gas flow rate can be continuously monitored and adjusted, as necessary.

This work is part of our broader commitment to refining the AML900 not just as a high speed LMD machine—but as a complete manufacturing solution. Whether for repair, coating, or full builds, our focus remains on delivering precision, repeatability, and practical value to our customers.

If you’re interested in how process-level improvements like this can benefit your application, or if you’d like to collaborate on testing advanced use cases—get in touch. We’re always open to pushing boundaries together.

.png?lang=en-US&ext=.png&maxsidesize=960&resizemode=force)