_1.jpg?width=794&height=642&ext=.jpg&maxsidesize=960&resizemode=force)

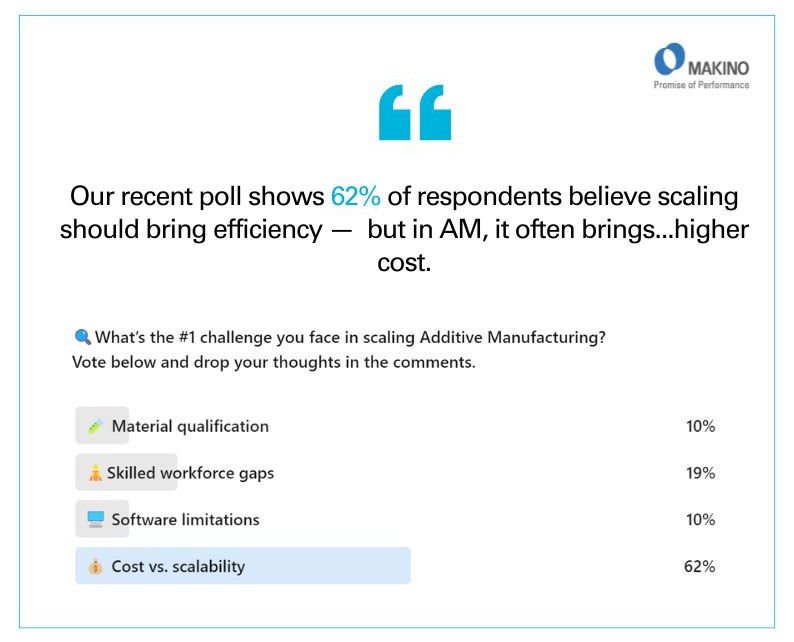

As strong advocates of hybrid manufacturing, we focus on seamlessly combining additive and subtractive processes within a single machine platform. This integratred approach unlocks signifcant efficiency gains, offering the ability to print and machine parts in a unified workflow. However, it also highlights an important truth: the hybrid machine is just one piece of a much larger puzzle.

Scaling additive manufacturing requires investments that go far beyond the build chamber. Key areas such inclued powder management, thermal processing, precision workholding, and automated part handling. Take material consistency, for example: to ensure stable and repeatable output, regular powder quality control and assessment are critical. This is especially true in hybrid environments, where the transition from build to cut must be precisely controlled to maintain both material intergrity and process reliability.

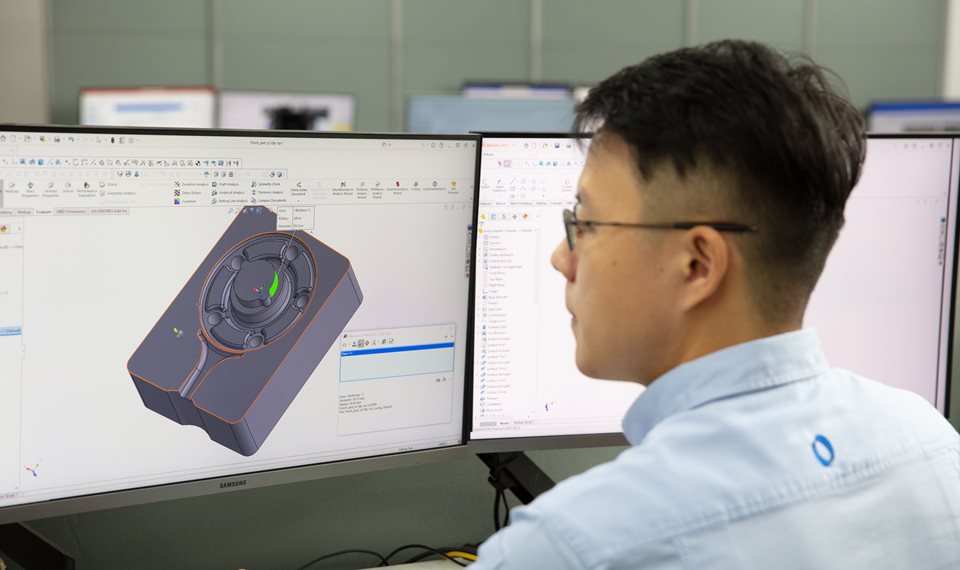

Producing a one-off hybrid part for prototyping is relatively straightforward. But scaling that process for production? That's where the real complexity begins. At Makino AM, we've made significant investments in comprehensive digital process chains - because scalable hybrid manufacturing demands workflows that are repeatable, traceable, and certifiable.

This means putting robust digital infrastructure in place, including:

At Makino, we don't see the cost of scaling additive manufacturing as a barrier - we see it as a strategic investment. By combining our legacy in precision machining with cutting-edge additive capabilities, we help customers move beyond early-stage challenges and into production-ready hybrid workflows.

Scaling additive manufacturing (AM) can seem costy — but with the right strategy, it unlocks transformative benefits: streamlined supply chains, on-demand production, unparalleled design flexibility, and part consolidation beyond the reach of traditional methods.

But scaling AM requires more than capital investment. It takes vision, seamless integration, and a trusted partner with deep, cross-disciplinary expertise. That’s where Makino AM comes in—combining strengths in material science, process development, and hybrid manufacturing to help our customers scale smarter, not just bigger.

Because the future of precision manufacturing isn’t additive or subtractive. It’s hybrid.

And we're here to help you make it a reality.